Abstract

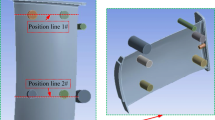

The current research of processing large size fabrication holes on complex spatial curved surface mainly focuses on the CNC flame cutting machines design for ship hull of ship manufacturing. However, the existing machines cannot meet the continuous cutting requirements with variable pass conditions through their fixed configuration, and cannot realize high-precision processing as the accuracy theory is not studied adequately. This paper deals with structure design and accuracy prediction technology of novel machine tools for solving the problem of continuous and high-precision cutting. The needed variable trajectory and variable pose kinematic characteristics of non-contact cutting tool are figured out and a metamorphic CNC flame cutting machine designed through metamorphic principle is presented. To analyze kinematic accuracy of the machine, models of joint clearances, manufacturing tolerances and errors in the input variables and error models considering the combined effects are derived based on screw theory after establishing ideal kinematic models. Numerical simulations, processing experiment and trajectory tracking experiment are conducted relative to an eccentric hole with bevels on cylindrical surface respectively. The results of cutting pass contour and kinematic error interval which the position error is from–0.975 mm to +0.628 mm and orientation error is from–0.01 rad to +0.01 rad indicate that the developed machine can complete cutting process continuously and effectively, and the established kinematic error models are effective although the interval is within a ‘large’ range. It also shows the matching property between metamorphic principle and variable working tasks, and the mapping correlation between original designing parameters and kinematic errors of machines. This research develops a metamorphic CNC flame cutting machine and establishes kinematic error models for accuracy analysis of machine tools.

Similar content being viewed by others

References

LIANG Guifang. Cutting technology handbook[M]. Beijing: China Machine Press, 1997. (in Chinese)

National Natural Science Fund Committee and Materials Science Branch. Report the mechanical engineering discipline development strategy (2011-2020)[M]. Beijing: Science Press, 2010. (in Chinese)

YANG Wenyu, YIN Zhouping, SUN Ronglei. Fundamentals of digital manufacturing[M]. Beijing: Beijing Institute of Technology Press, 2005. (in Chinese)

KOMATSUBARA H., MITOME K I, SASAKI Y A. A new cutting machine for elliptical cylinder[J]. Transactions of the Japan Society of Mechanical Engineers: Part C, 2007, 19(3): 891–896.

GORDON S, HILLERY M T. Development of a high-speed CNC cutting machine using linear motors[J]. Journal of Materials Processing Technology, 2005, 166(3): 321–329.

WANG Guodong, YAN Xiang’an, XIAO Juliang. Study on NC cutting of welding groove for intersecting of pipe and annulus[J]. Chinese Mechanical Engineering, 2005, 16(6): 561–563. (in Chinese)

SUN Yingda, CHEN Qiong. Control of a pipe-cutting machine[C] //International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, March 13–14, 2010: 845–848.

KLAUS D. Modern cutting machines and techniques in shipbuilding industry[J]. Svetsaren (a welding review published by ESAB), 2002, 57(1): 22–26.

TAYLOR R. Flame-cutting apparatus: European, EP 1867425. A1[P]. 2007-06-12.

RAIMONDI S. Laser cutting machine for metal sheets: European, EP2060358. A1[P]. 2007-11-14.

MARUYAMA Y, KAWAGUCHI T. Torch angle setting apparatus: USA, US6201207. B1[P]. 2000-03- 29.

WANG Zongyi, HU Shenghai, ZHAO Shijun. Design of big intersecting circle flame cutting machine[J]. Journal of Harbin Engineering University, 2003, 24(3): 258–262. (In Chinese)

DAI Jiansheng, ZHANG. Qixian. Metamorphic mechanisms and their configuration models[J]. Chinese Journal of Mechanical Engineering, 2000, 13(3): 212–218.

KUO Chinhsing, DAI Jiansheng, YAN Hongsen. Reconfiguration principles and strategies for reconfigurable mechanisms[C]//ASME/ IFToMM International Conference on Reconfigurable Mechanisms and Robots, London, United Kingdom, June 22–24, 2009: 1–7.

LEE K I, YANG S H. Measurement and verification of position-independent geometric errors of a five-axis machine tool using a double ball-bar[J]. International Journal of Machine Tools and Manufacture, 2013, 70: 45–52.

SEBASTIAN O H Madgwick, ANDREW J L Harrison, PAUL M. S, et al. Measuring motion with kinematically redundant accelerometer arrays: theory, simulation and implementation[J]. Mechatronics, 2013, 23(5): 518–529.

TSAI M J, LAI T H. Accuracy analysis of a multi-loop linkage with joint clearances[J]. Mechanism and Machine Theory, 2008, 43: 1141–1157.

FRISOLI A, SOLAZZI M, PELLEGRINETTI D, et al. A new screw theory method for the estimation of position accuracy in spatial parallel manipulators with revolute joint clearances[J]. Mechanism and Machine Theory, 2011, 46(12): 1929–1949.

HUANG Yonggang, DU Li, HUANG Maolin. Screw theory based error modeling method of robot mechanisms[J]. Journal of Harbin Institute of Technology, 2010, 42(3): 484–489. (In Chinese)

WU Weidong, RAO S S. Interval approach for the modeling of tolerances and clearances in mechanism analysis[J]. Journal of Mechanical Design, 2004, 126(4): 581–592.

WU Weidong, RAO S S. Uncertainty analysis and allocation of joint tolerances in robot manipulators based on interval analysis[J]. Reliability Engineering and System Safety, 2007, 92: 54–64.

CHAKER A, MLIKA A, LARIBI M A, et al. Clearance and manufacturing errors’ effects on the accuracy of the 3-RCC spherical parallel manipulator[J]. European Journal of Mechanics A/Solids, 2013, 37: 86–95.

KUMARASWAMY U, SHUNMUGAM M S, SUJATHA S. A unified framework for tolerance analysis of planar and spatial mechanisms using screw theory[J]. Mechanism and Machine Theory, 2013, 69: 168–184.

YU A, BONEV I A, ZSOMBOR-MURRAY P. Geometric approach to the accuracy analysis of a class of 3-DOF planar parallel robots[J]. Mechanism and Machine Theory, 2008, 43(3): 364–375.

BRIOT S, BONEV I A. Accuracy analysis of 3T1R fully-parallel robots[J]. Mechanism and Machine Theory, 2010, 45(5): 695–706.

DING Han, ZHU Limin. Geometric theories and methods for digital manufacturing of complex surface[M]. Beijing: Science Press, 2011. (in Chinese)

REN Fei, SUN Yuwen, GUO Dongming. Combined reparameterization-based spiral toolPath generation for five-axis sculptured surface machining[J]. International Journal of Advanced Manufacturing Technology, 2009, 40: 760–768.

YAO Yanan, ZHENG Ce, YAN Hongsen. Motion control of cam mechanisms[J]. Mechanism and Machine Theory, 2000, 35: 593–607.

WANG Delun, DAI Jiansheng. Theoretical foundation of metamorphic mechanism and its synthesis[J]. Chinese Journal of Mechanical Engineering, 2007, 43(8): 32–42. (in Chinese)

GRIGORE G. Mobility of mechanisms: a critical review[J]. Mechanism and Machine Theory, 2005, 40: 1068–1097.

MURRAY R M, LI Zexiang, SASTRY S S. A mathematical introduction to robotic manipulation[M]. Florida: CRC Press, 1994.

JIN Taiyi. Theory and application of precision[M]. Hefei: Press of University of Science and Technology of China, 2005. (In Chinese)

HU Shenghai, SHI Jianbin, ZHAN Guochen, et al. Accuracy analysis for high precision space curve numerical control cutting machine[J]. Journal of Harbin Engineering University, 2001, 22(6): 97–100. (in Chinese)

KIM H S, YONG J C. The kinematic error bound analysis of the stewart platform[J]. Journal of Robotic Systems, 2000, 17(1): 63–73.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China (Grant No. 51175099)

HU Shenghai, born in 1954, is currently a professor at Harbin Engineering University, China. His research interests include naval gun weapon system, NC machining technology, mechanical design theory.

ZHANG Manhui, born in 1991, is currently a PhD candidate at College of Mechanical and Electrical Engineering, Harbin Engineering University, China. His main research interests include metamorphic mechanism, NC machining technology.

ZHANG Baoping, born in 1990, is currently a master candidate at College of Mechanical and Electrical Engineering, Harbin Engineering University, China.

CHEN Xi, born in 1991, is currently a master candidate at College of Mechanical and Electrical Engineering, Harbin Engineering University, China.

YU Wei, born in 1989, is currently a master candidate at College of Mechanical and Electrical Engineering, Harbin Engineering University, China.

Rights and permissions

About this article

Cite this article

Hu, S., Zhang, M., Zhang, B. et al. Design and accuracy analysis of a metamorphic CNC flame cutting machine for ship manufacturing. Chin. J. Mech. Eng. 29, 930–943 (2016). https://doi.org/10.3901/CJME.2016.0425.059

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2016.0425.059