Abstract

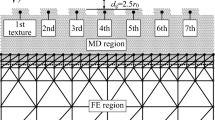

Detailed behaviors of nanoscale textured surfaces during the reciprocating sliding contacts are still unknown although they are widely used in mechanical components to improve tribological characteristics. The current research of sliding contacts of textured surfaces mainly focuses on the experimental studies, while the cost is too high. Molecular dynamics(MD) simulation is widely used in the studies of nanoscale single-pass sliding contacts, but the CPU cost of MD simulation is also too high to simulate the reciprocating sliding contacts. In this paper, employing multiscale method which couples molecular dynamics simulation and finite element method, two dimensional nanoscale reciprocating sliding contacts of textured surfaces are investigated. Four textured surfaces with different texture shapes are designed, and a rigid cylindrical tip is used to slide on these textured surfaces. For different textured surfaces, average potential energies and average friction forces of the corresponding sliding processes are analyzed. The analyzing results show that “running-in” stages are different for each texture, and steady friction processes are discovered for textured surfaces II, III and IV. Texture shape and sliding direction play important roles in reciprocating sliding contacts, which influence average friction forces greatly. This research can help to design textured surfaces to improve tribological behaviors in nanoscale reciprocating sliding contacts.

Similar content being viewed by others

References

RONEN A, ETSION I, KLIGERMAN Y. Friction-reducing surface-texturing in reciprocating automotive components[J]. Tribology Transactions, 2001,44(3): 359–366.

RYK G, KLIGERMAN Y, ETSION I. Experimental investigation of laser surface texturing for reciprocating automotive components[J]. Tribology Transactions, 2002, 45(4): 444–449.

ETSION I. Improving tribological performance of mechanical components by laser surface texturing[J]. Tribology Letters, 2004, 17(4): 733–737.

KLIGERMAN Y, ETSION I, SHINKARENKO A. Improving tribological performance of piston rings by partial surface texturing[J]. ASME Journal of Tribology, 2005, 127(3): 632–638.

MITCHELL N, ELJACH C, LODGE B, et al. Single and reciprocal friction testing of micropatterned surfaces for orthopedic device design[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2012, 7: 106–115.

SINGH R A, YOON ES. Friction of chemically and topographically modified Si (1 0 0) surfaces[J]. Wear, 2007, 263(7): 912–919.

MENEZES P L, KISHORE KAILASS V, et al. The role of surface texture on friction and transfer layer formation during repeated sliding of Al-4Mg against steel[J]. Wear, 2011, 271(9–10): 1785–1793.

GARRIDO A H, GONZÁLEZ R, CADENAS M, et al. Tribological behavior of laser-textured NiCrBSi coatings[J]. Wear, 2011, 271(5–6): 925–933.

CHOUQUET C, GAVILLET J, DUCROS C, et al. Effect of DLC surface texturing on friction and wear during lubricated sliding[J]. Materials Chemistry and Physics, 2010, 123(2–3): 367–371.

DENG J, SONG W, ZHANG H, et al. Friction and wear behaviors of the carbide tools embedded with solid lubricants in sliding wear tests and in dry cutting processes[J]. Wear, 2011, 270(9–10): 666–674.

PODGORNIK B, VILHENA L M, SEDLACEK M, et al. Effectiveness and design of surface texturing for different lubrication regimes[J]. Meccanica, 2012, 47(7): 1613–1622.

RAMESH A, AKRAM W, MISHRA S P, et al. Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication[J]. Tribology International, 2013, 57: 170–176.

KOVALCHENKO A, AJAYI O, ERDEMIR A, et al. Friction and wear behavior of laser textured surface under lubricated initial point contact[J]. Wear, 2011, 271(9–10): 1719–1725.

ACHANTA S, DREES D, CELIS J P. Friction and nanowear of hard coatings in reciprocating sliding at milli-Newton loads[J]. Wear, 2005, 259(1–6): 719–729.

PETTERSSON U, JACOBSON S. Textured surfaces for improved lubrication at high pressure and low sliding speed of roller/piston in hydraulic motors[J]. Tribology International, 2007, 40(2): 355–359.

SPIJKER P, ANCIAUX G, MOLINARI J F. Dry sliding contact between rough surfaces at the atomistic scale[J]. Tribology Letters, 2011, 44(2): 279–285.

QI Y, CHENG Y T, ÇAGIN T, et al. Friction anisotropy at Ni(100)/(100)interfaces: molecular dynamics studies[J]. Physical Review B, 2002, 66(8): 085420(1–7).

ZHANG Q, QI Y, HECTOR L G, et al. Atomic simulations of kinetic friction and its velocity dependence at Al/Al and a-Al2O3/a-Al2O3 interfaces[J]. Physical Review B, 2005, 72(4): 045406(1–12).

HARRISON J A, COLTON R J, WHITE C T, et al. Effect of atomic-scale surface roughness on friction: a molecular dynamics study of diamond surfaces[J]. Wear, 1993, 168(1–2): 127–133.

LUAN B Q, ROBBINS M O. Hybrid atomistic/continuum study of contact and friction between rough solids[J]. Tribology Letters, 2009, 36(1): 1–16.

JENG Y R, TSAI P C, FANG T H. Molecular dynamics studies of atomic-scale tribological characteristics for different sliding systems[J]. Tribology Letters, 2005, 18(3): 315–330.

TONG R T, LIU G, LIU T X. Multiscale analysis on two dimensional nanoscale sliding contacts of textured surfaces[J]. ASME Journal of Tribology, 2011, 133(4): 041401(1–13).

HARRISON J A, WHITE C T, COLTON R J, et al. Molecular-dynamics simulations of atomic-scale friction of diamond surfaces[J]. Physical Review B, 1992, 46(15): 9700–9708.

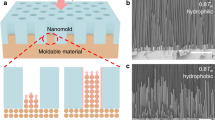

CHANDROSS M, LORENZ CD, STEVENSM J, et al. Simulations of nanotribology with realistic probe tip models[J]. Langmuir, 2008, 24(4): 1240–1246.

YUE L, ZHANG H, LI D Y. Defect generation in nano-twinned, nano-grained and single crystal Cu systems caused by wear: a molecular dynamics study[J]. Scripta Materialia, 2010, 63(11): 1116–1119.

ZHU P Z, HU Y Z, WANG H. Molecular dynamics simulations of atomic-scale friction in diamond-silver sliding system[J]. Chinese Science Bulletin, 2009, 54(24): 4555–4559.

LUAN B Q, HYUN S, MOLINARI J F. et al. Multiscale modeling of two-dimensional contacts[J]. Physical Review E, 2006, 74(4): 046710(1–11).

PANDURANGAN V, NG T, LI H. Nanoscratch simulation on a copper thin film using a novel multiscale model[J]. Journal of Nanomechanics and Micromechanics, 2013, 10.1061/(ASCE)NM.2153-5477.0000084: A4013008(1–8).

AGRAWAL P M, RICE B M, THOMPSON D L. Predicting trends in rate parameters for self-diffusion on FCC metal surfaces[J]. Surface Science, 2002, 515(1): 21–35.

DOLL J D, MCDOWELL H K. Theoretical studies of surface diffusion: self-diffusion in the FCC (111) system[J]. The Journal of Chemical Physics, 1982, 77(1): 479–483.

SWOPE W C, ANDERSEN H C, BERENS P H, et al. A computer simulation method for the calculation of equilibrium constants for the formation of physical clusters of molecules: application to small water clusters[J]. The Journal of Chemical Physics, 1982, 76(1): 637–649.

YANG J, KOMVOPOULOS K. A molecular dynamics analysis of surface interference and tip shape and size effects on atomic-scale friction[J]. ASME Journal of Tribology, 2005, 127(3): 513–521.

MOORE D F. Principles and applications of tribology[M]. Oxford: Pergamon Press, 1975.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China (Grant Nos. 51205313, 50975232), Fundamental Research Funds for the Central Universities of China (Grant No. 3102014JCS05009), and the 111 Project of China (Grant No. B13044)

TONG Ruiting, born in 1981, is currently an associate professor at Northwestern Polytechnical University, China. His research interests include multiscale method, contact mechanics, nanoscale friction, etc.

LIU Geng, born in 1961, is currently a professor at Northwestern Polytechnical University, China. His research interests include dynamics of mechanical system, tribology, contact mechanics, biomechanics, multiscale method, etc.

LIU Tianxiang, born in 1976, is currently are search fellow at Institute of Mechanics and Fluid Dynamics, TU Bergakademie Freiberg, Germany. His research interests include mesh free method, contact mechanics, nanoscale friction, etc.

Rights and permissions

About this article

Cite this article

Tong, R., Liu, G. & Liu, T. Two dimensional nanoscale reciprocating sliding contacts of textured surfaces. Chin. J. Mech. Eng. 29, 531–538 (2016). https://doi.org/10.3901/CJME.2016.0114.008

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2016.0114.008