Abstract

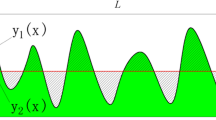

Neuber rule and Arola-Ramulu model are widely used to predict the stress concentration factor of rough specimens. However, the height parameters and effective valley radius used in these two models depend strongly on the resolution of the roughness-measuring instruments and are easily introduce measuring errors. Besides, it is difficult to find a suitable parameter to characterize surface topography to quantitatively describe its effect on stress concentration factor. In order to overcome these disadvantages, profile moments are carried out to characterize surface topography, surface topography is simulated by superposing series of cosine components, the stress concentration factors of different micro cosine-shaped surface topographies are investigated by finite element analysis. In terms of micro cosine-shaped surface topography, an equation using the second profile moment to estimate the stress concentration factor is proposed, predictions for the stress concentration factor using the proposed expression are within 10% error compared with the results of finite element analysis, which are more accurate than other models. Moreover, the proposed equation is applied to the real surface topography machined by turning. Predictions for the stress concentration factor using the proposed expression are within 10% of the maximum stress concentration factors and about 5% of the effective stress concentration factors estimated from the finite element analysis for three levels of turning surface topographies under different simulated scales. The proposed model is feasible in predicting the stress concentration factors of real machined surface topographies.

Similar content being viewed by others

References

GRIFFITHS B. Manufacturing surface technology. surface integrity and functional performance[M]. London: Penton Press, 2001.

JUVINALL R C. Engineering considerations of stress, strain and strength[M]. McGraw-Hill, 1967.

JUVINALL R C, MARSHEK K M. Fundamentals of machine component design[M]. New York: John Willey & Sons, Inc., 1991.

MCKELVEY S A, FATEMI A. Surface finish effect on fatigue behavior of forged steel[J]. International Journal of Fatigue, 2012, 36: 130–145.

SURARATCHI M, LIMIDO J, MABRU C, et al. Modeling the influence of machined surface roughness on the fatigue life of aluminium alloy[J]. International Journal of Fatigue, 2008, 30: 2119–2126.

ZAHAVI E, TORBILO V. Fatigue design: life expectancy of machine parts[M]. 1st ed. Boca Raton, Florida: CRC Press, 1996.

ARDI D T, LI Y G, CHAN K H K, et al. The effects of machined topography on fatigue life of a nickel based superalloy[C]//2nd CIRP Conference on Surface Integrity(CSI), Nottingham, Britain, May 28–30, 2014, 13: 19–24.

AROLA D, WILLIAMS C L. Estimating the fatigue stress concentration factor of machined surfaces[J]. International Journal of Fatigue, 2002, 24: 923–930.

AONO Y, NOGUCHI H. Fatigue limit reliability of axisymmetric complex surface[J]. International Journal of Fracture, 2005, 131: 59–78.

NEUBER H. Kerbspannungslehre[M]. Berlin: Springer, 1958.

AROLA D, RAMULU M. An examination of the effects from surface texture on the strength of fiber-reinforced plastics[J]. Journal of Composite Materials, 1999, 33(2): 101–123.

MAJUMDAR A, TIEN C L. Fractal characterization and simulation of rough surfaces[J]. Wear, 1990, 136: 313–327.

AS S K, SKALLERUD B, TVEITEN B W, et al. Fatigue life prediction of machined components using finite element analysis of surface topography[J]. International Journal of Fatigue, 2005, 27: 1590–1596.

AS S K, SKALLERUD B, TVEITEN B W. Surface roughness characterization for fatigue life predictions using finite element analysis[J]. International Journal of Fatigue, 2008, 30: 2200–2209.

CHIFFRE L De, LEONARDO P, TRUMPOLD H, et al. Quantitative characterization of surface texture[J]. Annals of the CIRP, 2000, 49(2): 635–652.

THOMAS T R. Rough surfaces[M]. 2nd ed. London: Imperial College Press, 1999.

FREUND L B, SURESH S. Thin film materials: Stress, defect formation and surface evolution[M]. Cambridge: Cambridge University Press, 2003.

NOVOVIC D, DEWES R C, ASPINWALL D K, et al. The effect of machined topography and integrity on fatigue life[J]. International Journal of Machine Tools and Manufacture, 2004, 44: 125–134.

MURAKAMI Y. Metal fatigue: effects of small defects and nonmetallic inclusions[M]. Elsevier, 2002.

MIYAZAKI T, AONO Y, NOGUCHI H. A practical stress analysis for predicting fatigue limit of metal with axisymmetric complex surface[J]. International Journal of Fracture, 2007, 143: 355–367.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Defense Preliminary Research Project of China (Grant No. 104010205)

CHENG Zhengkun, born in 1986, is currently a PhD candidate at Research Center for Power Machinery, School of Mechanical Engineering, Beijing Institute of Technology, China. His research interest is structural strength and reliability analysis, focusing on metal fatigue behavior induced by machining defects.

LIAO Ridong, born in 1972, is currently a professor at Beijing Institute of Technology. He received his PhD degree from Beijing Institute of Technology, China, in 1999. His research interests include structure strength and surface reinforcement technology.

Rights and permissions

About this article

Cite this article

Cheng, Z., Liao, R. Effect of surface topography on stress concentration factor. Chin. J. Mech. Eng. 28, 1141–1148 (2015). https://doi.org/10.3901/CJME.2015.0424.047

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2015.0424.047