Abstract

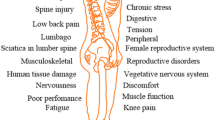

The ride comfort experimental assessment of crawler off-road vehicle is relatively overlooked, and is expensive and difficult to execute with higher and higher ride comfort performance requirements. To trade off between precise and cost, an experimental method based on the similitude theory is proposed. Under the guidance of the similitude theory, a 1:5 crawler power chassis scale model equipped with a kind of variable stiffness suspension system is used. The power spectrum density(PSD), the root mean square(RMS) of weighed acceleration, peak factor, average absorbed power(AAP) and vibration dose value(VDV) are selected as ride comfort evaluation indexes, and tests results are transformed via similarity indexes to predict the performance of full-scale power chassis. PSD shows that the low-order natural frequency of the vertical natural frequency(z axis) is 1.1 Hz, and the RMS, AAP and VDV values indicate the ride comfort performance of this kind of power chassis is between the “A little uncomfortable” and “Rather uncomfortable”. From the results, low-order vertical natural frequency, obtained by PSD, validates that the similarity relationship between two models is satisfied, and 1:5 scale model used in experiment meets the similarity relationship with the full-scale model; consequently, the ride comfort prophase evaluation with the 1:5 scale model is feasible. The attempt of applying the similitude theory to crawler vehicle ride comfort test study decreases the cost and improves the test feasibility with sufficient test precise.

Similar content being viewed by others

References

SOLOMON U, PADMANABHAN C. Hydro-gas suspension system for a tracked vehicle: Modeling and analysis[J]. Journal of Terramechanics, 2011, 48(2): 125–137.

UYS P E, ELS P S, THORESSON M. Suspension settings for optimal ride comfort of off-road vehicles travelling on roads with different roughness and speeds[J]. Journal of Terramechanics, 2007, 44(2): 163–175.

SHI Jianpeng. Vehicle ride comfort based on matching suspension system[J]. Chinese Journal of Mechanical Engineering, 2011, 24(2): 271–276.

RYU S, PARK Y, SUH M. Ride quality analysis of a tracked vehicle suspension with a preview control[J]. Journal of Terramechanics, 2011, 48(6): 409–417.

PAZOOKI A, RAKHEJA S, CAO D. Modeling and validation of off-road vehicle ride dynamics[J]. Mechanical Systems and Signal Processing, 2012, 28: 679–695.

YAMAKAWA J, WATANABE K. A spatial motion analysis model of tracked vehicles with torsion bar type suspension. Journal of Terramechanics, 2004, 41: 113–126.

YANG Bo, WANG Xuelin, HU Yujin, et al. Flexible model of multi-axle vehicle ride comfort[J]. Chinese Journal of Mechanical Engineering, 2003, 39(12): 145–150. (in Chinese)

ZHANG Xiaoyang, SUN Beibei, SUN Qinghong, et al. Vehicle and terrain interaction based in Adams-Matlab co-simulation[J]. Journal of Southeast University(English Edition), 2009, 25(03): 335–339.

GUO Jun, WANG Shenshen, LI Xiaolei. Dynamic simulation of tracked vehicle using the DADS software[J]. Journal of Beijing Institute of Technology(English Edition), 2001, 10 (04): 370–375.

MEHTA C R, SHYAM M, SINGH Pratap, et al. Ride vibration on tractor-implement system[J]. Applied Ergonomics, 2000, 31(3): 323–328.

ELS P S. The applicability of ride comfort standards to off-road vehicles[J]. Journal of Terramechanics, 2005, 42(1): 47–64.

TANG Chuanyin, ZHANG Yimin, ZHAO Guangyao, et al. Annoyance rate evaluation method on ride comfort of vehicle suspension system[J]. Chinese Journal of Mechanical Engineering, 2014, 27(2): 296–303.

CHEN Bincong. Similitude theory and model experiments[J]. Tractor, 1979 (2): 9–19. (in Chinese)

ZHAO Jianzhu, WANG Fengchen, YU Bin, et al. Research on all-terrain profiling crawler power chassis[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(9): 20–24.

ZHU Yonghua, HOU Jianxun, ZHOU Yiming. A model test method in dynamic performance of tractor overturning—The development of a remote-control scale model tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 1986, 9(3): 17–23. (in Chinese)

International Organization for Standardization. ISO 2631-1:1997 Mechanical vibration and shock-Evaluation of human exposure to whole-body vibration-Part 1: General requirements[S]. Geneva: International Organization for Standardization, 1997.

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. GB/T 4970-2009 Method of running test-Automotive ride comfort[S]. Beijing: China Standard Publishing House, 2009. (in Chinese)

DIXON J C. Tyres, suspension and handling[M]. Cambridge: Cambridge University Press, 1991.

BAKER W E, WESTINE P S, DODGE F T. Similarity methods in engineering dynamics: theory and practice of scale modeling[M]. Rochelle Park: Hayden Book Company, Inc., 1973.

SCHURING D J. Scale models in engineering[M]. Oxford: Oxford Pergamon Press, 1977.

LI Debao, LU Qiuhai. Analysis of experiments in engineering vibration[M]. Beijing: Tsinghua University Press, 2004. (in Chinese)

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. GB/T 7031-2005 Mechanical vibration-Road surface profiles-Reporting of measured data[S]. Beijing: China Standard Publishing House, 2005. (in Chinese)

PRADKO F, LEE R, KALUZA V. Theory of human vibration response [R]. Michigan: Army Tank-Automotive Center Warren MI, 1966.

HUANG Jinying, PAN Hongxia, ZHANG Xiaoqiang, et al. Vibration spectrum measurement and analysis of track vehicle[J]. Journal of Vibration, Measurement & Diagnosis, 2009, 29(4): 457–461.

ZHANG H, WANG E, MIN F, et al. Skyhook-based semi-active control of full-vehicle suspension with magneto-rheological dampers[J]. Chinese Journal of Mechanical Engineering, 2013, 26(3): 498–505.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by Special Fund for Argo-scientific Research in the Public Interest, China(Grant No. 201203024), and National Natural Science Foundation of China(Grant No. 51175498)

ZHAO Jianzhu, born in 1963, is currently an associate professor at College of Engineering, China Agricultural University, China. He received his master degree on agricultural machinery engineering from China Agricultural University, China, in 2006. His main research interests include vehicle dynamics, agricultural equipment engineering.

WANG Fengchen, born in 1991, is currently a master candidate at College of Engineering, China Agricultural University, China.

YU Bin, born in 1991, is currently a master candidate at College of Engineering, China Agricultural University, China.

TONG Pengcheng, born in 1994, is currently an undergraduate candidate at College of Science, China Agricultural University, China.

CHEN Kuifu, born in 1969, is currently a professor at College of Science, China Agricultural University, China. He received his PhD degree from Peking Union Medical College, China, in 2000. His main research interests include vibration control and biomechanics.

Rights and permissions

About this article

Cite this article

Zhao, J., Wang, F., Yu, B. et al. Experimental study on the ride comfort of a crawler power chassis scale model based on the similitude theory. Chin. J. Mech. Eng. 28, 496–503 (2015). https://doi.org/10.3901/CJME.2015.0306.024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2015.0306.024