Abstract

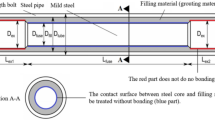

Conventional analytical and numerical methods for the mechanical properties of helical threads are relied on many assumptions and approximations and thus hardly yield satisfied results. A parameterized 3D finite element model of bolted joints with real helical thread geometry is established and meshed with refined hexahedral elements. The Von Mises plasticity criterion, kinematic hardening rule of materials and interfacial contacts are employed to make it possible for the suggested model be able to approach real assembly conditions. Then, the mechanical properties of bolted joints with different thread pitches, thread numbers and modular ratios are investigated, including the contact pressure distribution at joint interfaces, the axial load distribution and stress concentration in screw threads during the loading and unloading process. Simulation results indicate that the load distribution in screw threads produced by the suggested model agrees well the results from CHEN’s photoelastic tests. In addition, an interesting phenomenon is found that tightening the bolt with a large preload first and then adjusting the clamping force by unloading can make the load distribution more uniform and reduce the maximum residual equivalent stress in thread roots by up to 40%. This research provides a simple and practical approach to constructing the 3D finite element model and predicting the mechanical properties of helical thread connection.

Similar content being viewed by others

References

ZUO Dawei, CHEN Xiumin, SHEN Guangxian. Experimental study on the load distribution of plate mill pressure screw-pairs[J]. China Mechanical Engineering, 2006, 17(3): 307–311. (in Chinese)

MARINO R L, RILEY W F. Optimizing thread-root contours using photoelastic methods[J]. Experimental Mechanics, 1964, 4(1): 1–10.

DRAGONI E. Effect of thread shape on screw stress concentration by photoelastic measurements[J]. Journal of Offshore Mechanics and Arctic Engineering, 1994, 116(4): 228–232.

CHEN Haiping, ZENG Pan, FANG Gang, et al. Load distribution of bolted joint[J]. Journal of Mechanical Engineering, 2010, 46(9): 171–178. (in Chinese)

YAMATOTO A. The theory and computation of threads connection[M]. Tokoy: Yokendo, 1980. (in Japanese)

WANG W, MARSHEK K M. Determination of load distribution in a threaded connector with yielding threads[J]. Mechanism and Machine Theory, 1996, 31(2): 229–244.

KIM J, YOON J C, KANG B S. Finite element analysis and modeling of structure with bolted joints[J]. Applied Mathematical Modelling, 2007, 31(5): 895–911.

YANG Guoqing, HONG Jun, WANG Ning, et al. Member stiffnesses and interface contact characteristics of bolted joints[C]//Proceedings 2011 IEEE International Symposium on Assembly and Manufacturing (ISAM 2011), Tampere, Finland, May 25–27, 2011: 1–6.

NASSAR S A, WU Zhijun, YANG Xianjie. Achieving uniform clamp load in gasketed bolted joints using a nonlinear finite element model[J]. Journal of Pressure Vessel Technology-Transactions of the ASME, 2010, 132(3): 1–10.

OSKOUEI R H, KEIKHOSRAVY M, SOUTIS C. Estimating clamping pressure distribution and stiffness in aircraft bolted joints by finite-element analysis[J]. Proceedings of the Institution of Mechanical Engineers Part G: Journal of Aerospace Engineering, 2009, 223(7): 863–871.

CHEN Shoujun, LI Qiang, ZHANG Yi, et al. Research on deformation and stress distribution on thread teeth at conic thread connections[J]. China Mechanical Engineering, 2010, 21(17): 2 044–2 049. (in Chinese)

LIAO Ridong, SUN Yujuan, ZHANG Weizheng. Nonlinear analysis of axial-load and stress distribution for threaded connection[J]. Chinese Journal of Mechanical Engineering, 2009, 22(6): 869–875.

FUKUOKA T. Finite element analysis of the thermal and mechanical behavior of a bolted joint[J]. Journal of Pressure Vessel Technology-Transactions of the ASME, 2005, 127(4): 402–407.

IZUMI S, YOKOYAMA T, IWASAKI A, et al. Three-dimensional finite element analysis of tightening and loosening mechanism of threaded fastener[J]. Engineering Failure Analysis, 2005, 12(4): 604–615.

FUKUOKA T, NOMURA M. Proposition of helical thread modeling with accurate geometry and finite element analysis[J]. Journal of Pressure Vessel Technology-Transactions of the ASME, 2008, 130(1): 1–6.

FUKUOKA T, NOMURA M. True cross sectional area of screw threads with helix and root radius geometries taken into consideration[J]. Journal of Pressure Vessel Technology, 2009, 131(2): 024501.1–024501.5.

Author information

Authors and Affiliations

Corresponding author

Additional information

This project is supported by National Natural Science Foundation of China (Grant No. 50935006), Major Project of High-end CNC Machine Tool and Basic Manufacturing Equipment of China (Grant No. 2011ZX04016-031), and National Hi-tech Research and Development Program of China (863 Program, Grant No. 2012AA040701)

YANG Guoqing, born in 1976, is currently a PhD candidate at State Key Laboratory for Manufacturing Systems Engineering, Xi’an Jiaotong University, China. He received his master degree on mechatronics from Central South University, China, in 2004. His research interests include mechatronics engineering and digital design.

HONG Jun, born in 1968, is currently a professor at Xi’an Jiaotong University, China. He received his PhD degree from Xi’an Jiaotong Universtiy, China, in 2001. His research interests include mechatronics engineering and digital design.

ZHU Linbo, born in 1985, is currently a PhD candidate at State Key Laboratory for Manufacturing Systems Engineering, Xi’an Jiaotong University, China.

LI Baotong, born in 1982, is currently a PhD candidate at State Key Laboratory for Manufacturing Systems Engineering, Xi’an Jiaotong University, China.

XIONG Meihua, born in 1976, is currently a Lecturer at Hunan University of Science and Technology, China.

WANG Fei, born in 1987, is currently a master candidate at State Key Laboratory for Manufacturing Systems Engineering, Xi’an Jiaotong University, China.

Rights and permissions

About this article

Cite this article

Yang, G., Hong, J., Zhu, L. et al. Three-dimensional finite element analysis of the mechanical properties of helical thread connection. Chin. J. Mech. Eng. 26, 564–572 (2013). https://doi.org/10.3901/CJME.2013.03.564

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2013.03.564