Abstract

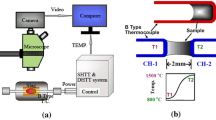

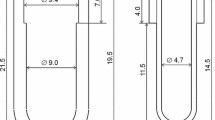

The castings defects are affected by the melting volume change rate of material. The change rate has an important effect on running safety of the high temperature thermal storage chamber, too. But the characteristics of existing measuring installations are complex structure, troublesome operation and low precision. In order to measure the melting volume change rate of material accurately and conveniently, a self-designed measuring instrument, self-heating probe instrument, and measuring method are described. Temperature in heating cavity is controlled by PID temperature controller; melting volume change rate υ and molten density are calculated based on the melt volume which is measured by the instrument. Positive and negative υ represent expansion and shrinkage of the sample volume after melting, respectively. Taking eutectic LiF+CaF2 for example, its melting volume change rate and melting density at 1 123 K are −20.6% and 2 651 kg·m−3 measured by this instrument, which is only 0.71% smaller than literature value. Density and melting volume change rate of industry pure aluminum at 973 K and analysis pure NaCl at 1 123 K are detected by the instrument too. The measure results are agreed with report values. Measuring error sources are analyzed and several improving measures are proposed. In theory, the measuring errors of the change rate and molten density which are measured by the self-designed instrument is nearly 1/20−1/50 of that measured by the refitted mandril thermal expansion instrument. The self-designed instrument and method have the advantages of simple structure, being easy to operate, extensive applicability for material, relatively high accuracy, and most importantly, temperature and sample vapor pressure have little effect on the measurement accuracy. The presented instrument and method solve the problems of complicated structure and procedures, and large measuring errors for the samples with high vapor pressure by existing installations.

Similar content being viewed by others

References

CHENG Sujuan, DONG Qiguo, WANG Zhonghua, et al. Mechanism of micro-thermal contraction of atom clusters in metal melts[J]. Rare Metal Materials and Engineering, 2010, 39(2): 219–223. (in Chinese)

DING Yutian, CAO Jun, HU Yong, et al. Effects of annealing and drawing on properties of single crystal copper bonding wire[J]. Journal of Mechanical Engineering, 2009, 45(4): 83–88. (in Chinese)

YE Xicong, SU Yanting, GUO Jingjie, et al. Numerical simulation on suction casting defects of TiAl based alloy blade[J]. Rare Metal Materials and Engineering, 2011, 40(2): 47–250. (in Chinese)

FAN Jinhui, WEI Bing, WANG Feng. Systematic and dynamic properties of casting hot spot[J]. Chinese Journal of Mechanical Engineering, 2003, 16(2): 153–155.

YOU Dongdong, SHAO Ming, ZHOU Zhaoyao, et al. Development of the mold-temperature-control solidification instrument with individual temperature control units[J]. Chinese Journal of Mechanical Engineering, 2007, 43(10): 187–195. (in Chinese)

MEDRANO M, GIL A, MARTORELL I, et al. State of the art on high-temperature thermal energy storage for power genera- tion. Part 2-Case studies[J]. Renewable and Sustainable Energy Reviews, 2010, 14(1): 56–72.

ALKILANI M M, SOPIAN K, ALGHOUL M A, et al. Review of solar air collectors with thermal storage units[J]. Renewable and Sustainable Energy Reviews. 2011. 15(3): 955–970.

HOSHI A, MILLS D R, BITTAR A, et al. Screening of high melting point phase change materials (PCM) in solar thermal concentrating technology based on CLFR[J]. Solar Energy, 2005, 79(3): 332–339.

ZHENG Weitao, YU Ruihuang. A study of the binding energy and volume thermal expansion coefficient for noble metals[J]. Metal Science and Technology, 1991, 10(4): 24–28. (in Chinese)

GIL A, MEDRANO M, MARTORELL I, et al. State of the art on high temperature thermal energy storage for power generation. Part 1-Concepts, materials and modellization[J]. Renewable and Sustainable Energy Reviews, 2010, 14(1): 31–35.

SHARMA A, TYAGI V V, CHEN C R, et al. Review on thermal energy storage with phase change materials and applications [J]. Renewable and Sustainable Energy Reviews, 2009, 13(2): 318–345.

KENISARIN M M. High-temperature phase change materials for thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2010, 14(3): 955–970.

BIAN Maoshu, MA Luming, WANG Jingtang. A new method for measuring density of high temperature melt[J]. Acta Metallurgica Sinica, 1986, 22(2): B90–B96.

BLUMM J, HENDERSON J B. Measurement of the volumetric expansion and density change of metals in the solid and molten regions[J]. High Temperatures-High Pressures, 2000, 32(1): 109–113.

WHITTENBERGER J D. Tensile properties of harynes alloy 230 and Inconel 617 after long exposures to LiF-22CaF2 and vacuum at 1 093 K[J]. Journal of Materials Engineering and Performance, 1994, 3(6): 763–774.

BIAN Maoshu, CHEN Qiu, WANG Jingtang. Density surface tension wet ability and adhesive power of liquid Al and Al-RE alloy in BN surface[J]. Acta Metallurgica Sinica, 1988, 24(2): B139–B141. (in Chinese)

KIRSHENBAUM A D, CAHILL J A, MCGONIGAL P J, et al. The density of liquid NaCl and KCl and an estimate of their critical constants together with those of the other alkali halides[J]. Journal of Inorganic and Nuclear Demistry, 1962, 24(10): 1 287–1 296.

Author information

Authors and Affiliations

Corresponding author

Additional information

This project is supported by Gansu Provincial Critical Patented Projects of China(Grant No. 1101ZSB117), and Gansu Provincial Science and Technology Pillar Program of China(Grant No. 1002ZSB018)

WANG Junwei, born in 1986, is currently a PhD candidate at College of Materials Science and Engineering, Lanzhou University of Technology, China. He received his master degree from Lanzhou University of Technology, China, in 2010. His research interests include solar thermal power technology and solidified microstructure control.

WANG Zhiping, born in 1956, is currently a professor at State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology, and Renewable Energy Laboratory, Lanzhou University of Technology, China. His research interests include solar thermal power technology and solidified microstructure control.

LU Yang, born in 1957, is currently a professor at State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology, China. Her research interests include solidified microstructure control.

CHENG Bo, born in 1987, is currently a master candidate at College of Materials Science and Engineering, Lanzhou University of Technology, China. His research interests is solar thermal power technology and hot corrosion.

Rights and permissions

About this article

Cite this article

Wang, J., Wang, Z., Lu, Y. et al. Self-heating probe instrument and method for measuring high temperature melting volume change rate of material. Chin. J. Mech. Eng. 26, 371–376 (2013). https://doi.org/10.3901/CJME.2013.02.371

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2013.02.371