Abstract

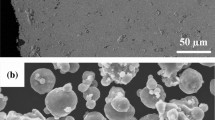

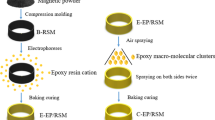

The sintered NdFeB permanent magnets are widely used in various industries because of their excellent magnetic and comprehensive properties. However, they are seriously hindered to further developments and applications owing to its poor corrosion resistance. In this paper, TiO2/acrylic resin composite coatings were successfully prepared on the sintered NdFeB permanent magnets by electrochemical deposition for the first time, and the corrosion behaviors were investigated by using immersion testing and potentiodynamic polarization tests. It is found that the coating is a composite, being composed of polymerized acrylic resin as the matrix and nano-rutile TiO2 particles (−200 nm) as the reinforcements. It is about 25 μm in thickness and its surface and cross-section exhibit uniform and smooth with no pores, cracks, and other defects. Compared with those of the uncoated NdFeB magnets, the weight loss of the coated samples immersed in H2SO4 solution reduces by two orders of magnitude, corrosion current density decreases by four orders of magnitude, and the corrosion potential of the coated sample is shifted in the noble direction by 400 mV. The mechanisms of corrosive resistance enhancement were discussed.

Similar content being viewed by others

References

Eisch OG, Willard MA, Brück E, Chen CH, Sankar SG, Liu JP. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv Mater. 2011;23(7):821.

Li W, Pan W, Guo YQ, Guo ZH, Zhu MG, Li AH, Li XM, Cui JW. Research progress on high performance Nd–Fe–B permanent magnet. Phys Stat Sol. 2007;4(12):4611.

Davies BE, Mottram RS, Harris IR. Recent developments in the sintering of NdFeB. Mater Chem Phys. 2001;67(1–3):272.

Matsuura Y. Recent development of Nd–Fe–B sintered magnets and their applications. J Magn Magn Mater. 2006;303(2):344.

Vial F, Joly F, Nevalainen E, Sagawa M, Hiraga K, Park KT. Improvement of coercivity of sintered NdFeB permanent magnets by heat treatment. J Magn Magn Mater. 2002;242–245(2):1329.

Man HH, Man HC, Leung LK. Corrosion protection of NdFeB magnets by surface coatings—Part 2: electrochemical behaviour in various solutions. J Magn Magn Mater. 1996;152(1–2):47.

Jan G, McGuiness PJ, Farr JPG, Harris IR. Environmental degradation of NdFeB magnets. J Alloys Compd. 2009;478(1–2):188.

Song YW, Zhang H, Yang HX. A comparative study on the corrosion behavior of NdFeB magnets in different electrolyte solutions. Mater Corros. 2008;59(10):794.

El-Moneim AA, Gebert A, Uhlemann M, Gutfleisch O, Schultz L. The influence of Co and Ga additions on the corrosion behavior of nanocrystalline NdFeB magnets. Corros Sci. 2002;44(8):1857.

Fernengel W, Rodewald W, Blank R, Schrey P, Katter M, Wall B. The influence of Co on the corrosion resistance of sintered Nd-Fe-B magnets. J Magn Magn Mater. 1999;196–197(5):288.

Murakami RK, Rechenberg HR, Neiva AC, Missell FP, Villas-Boas V. Effect of Ti and C additions on structural and magnetic properties of (Pr, Nd)–Fe–B nanocrystalline magnetic materials. J Magn Magn Mater. 2008;320(14):e65.

Yu LQ, Wen YH, Yan M. Effects of dy and Nbon the magnetic properties and corrosion resistance of sintered NdFeB. J Magn Magn Mater. 2004;283(2–3):353.

Takeuchi SMT, Azambuja DS, Saliba-Silva AM, Costa I. Corrosion protection of NdFeB magnets by phosphating with tungstate incorporation. Surf Coat Technol. 2006;200(24):6826.

Yang XK, Li Q, Zhang SY, Zhong XK, Dai Y, Luo F. Electrochemical corrosion behaviors and protective properties of Ni–Co–TiO2 composite coating prepared on sintered NdFeB magnet. Mater Corros. 2010;61(7):618.

Song LZ, Wang YN, Lin WZ, Liu Q. Primary investigation of corrosion resistance of Ni–P/TiO2 composite film on sintered NdFeB permanent magnet. Surf Coat Technol. 2008;202(21):5146.

Li JL, Mao SD, Sun KF. AlN/Al dual protective coatings on NdFeB by DC magnetron sputtering. J Magn Magn Mater. 2009;321(22):3799.

Wongsarat W, Sarapirom S, Aukkaravittayapun S. Plasma immersion ion implantation and deposition of DLC coating for modification of orthodontic magnets. Nucl Instrum Method B. 2012;272(2):346.

Mao SD, Yang HX, Huang F, Xie TT, Song ZL. Corrosion behaviour of sintered NdFeB coated with Al/Al2O3 multilayers by magnetron sputtering. Appl Surf Sci. 2011;257(9):3980.

Li Q, Yang XK, Zhang L, Wang JP, Chen B. Corrosion resistance and mechanical properties of pulse electrodeposited Ni-TiO2 composite coating for sintered NdFeB magnet. J Alloys Compd. 2009;482(1–2):339.

Liu F, Li Q, Yang XK, Dai Y, Luo F, Wang SY, Zhang HX. Corrosion resistance of environment-friendly sealing layer for Zn-coated sintered NdFeB magnet. Mater Corros. 2011;62(12):1141.

Yan M, Ying HG, Ma TY. Preparation of coatings with high adhesion strength and high corrosion resistance on sintered Nd–Fe–B magnets through electroless plating. Mater Chem Phys. 2009;113(2–3):764.

Yao ZP, Jiang YL, Jiang ZH, Wang FP, Wu ZD. Preparation and structure of ceramic coatings containing zirconium oxide on Ti alloy by plasma electrolytic oxidation. J Mater Process Technol. 2008;205(1–3):303.

Palcut M, Mikkelsen L, Neufeld K, Chen M, Knibbe R, Hendriksen PV. Corrosion stability of ferritic stainless steels for solid oxide electrolyser cell interconnects. Corros Sci. 2010;52(10):3309.

Gurappa I. Suitability of Nd–Fe–B permanent magets for biomedical application-a corrosion study. J Alloys Compd. 2002;339(1):241.

Zhang H, Song YW, Song ZL. Electrodeposited nickel/alumina composite coating on NdFeB permanent magnets. Mater Corros. 2008;59(4):324.

Schultz L, El-Aziz AM, Barkleit G, Mummert K. Corrosion behaviour of Nd–Fe–B permanent magnetic alloys. Mater Sci Eng, A. 1999;267(2):307.

Gurappa I. Corrosion characteristics of permanent magnets in acidic environments. J Alloys Compd. 2003;360(1–2):236.

Annett DR, Schurer C, Irmer G, Muller E. Electrochemical corrosion behaviour of uncoated and DLC coated medical grade Co28Cr6Mo. Surf Coat Technol. 2004;177–178(1):830.

Acknowledgments

This study was financially supported by the National Science and Technology Key Support Projects of China (No. 2012BAE02B01), the Major Science and Technology Special Projects of Jiangxi Province (No. 2010AZX00200), the Science and Technology Plan Projects of Jiangxi Province (Industrial field) (No. 20121BBE50001), and the Science and Technology Plan Projects of Department of Education of Jiangxi Province (No. KJ201109132281).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, ZC., Xu, JL., Huang, ZX. et al. Preparation and characterization of TiO2/acrylic resin composite coatings on sintered NdFeB permanent magnets by electrochemical deposition. Rare Met. 33, 703–708 (2014). https://doi.org/10.1007/s12598-013-0142-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0142-x