Abstract

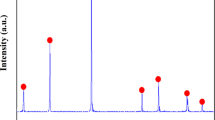

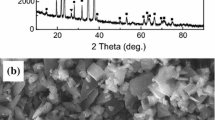

B4C-TiB2-Al composites were fabricated by infiltrating aluminum into porous B4C-TiB2 preforms in vacuum. The microstucture and mechanical properties of the B4C-TiB2-Al composites were investigated. The hardness decreased, the flexural strength increased, and the fracture toughness first increased and then decreased slightly with an increase in TiB2 content. The B4C-TiB2-Al composite with 40wt.% TiB2 showed the optimized properties. The infiltrated aluminum addition was the leading reason for the fracture toughness improvement of the composites. The tear ridges and dimples on the fracture surface of the composites increased gradually with the increase of infiltrated aluminum content showing inter/transgranular fracture mode. The relationships between the microstructures and the mechanical properties of the composites were discussed.

Similar content being viewed by others

References

Fanchini G., Gupta V., Mann A.B., and Chhowalla M., In situ monitoring of structural changes in boron carbide under electric fields, J. Am. Ceram. Soc., 2008, 91(8): 2666.

Hayun S., Rittel D., Frage N., and Dariel M.P., Static and dynamic mechanical properties of infiltrated B4C-Si composites, Mater. Sci. Eng. A, 2008, 487(1–2): 405.

Larsson P., Axén N., and Hogmark S., Improvements of the microstructure and erosion resistance of boron carbide with additives, J. Mater. Sci., 2000, 35(14): 3433.

Roy T.K., Subramanian C., and Suri A.K., Pressureless sintering of boron carbide, Ceram. Int., 2006, 32(3): 227.

Thévenot F., Boron carbide—A comprehensive review, J. Eur. Ceram. Soc., 1990, 6(4): 205.

Lee H., Speyer R.F., and Hackenberger W.S., Sintering of boron carbide heat-treated with hydrogen, J. Am. Ceram. Soc., 2002, 85(8): 2131.

Chen M.W., McCauley J.W., LaSalvia J.C., and Hemker K.J., Microstructural characterization of commercial hot-pressed boron carbide ceramics, J. Am. Ceram. Soc., 2005, 88(7): 1935.

Halverson D.C., Pyzik A.J., Aksay I.A., and Snowden W.E., Processing of boron carbide-aluminium composites, J. Am. Ceram. Soc., 1989, 72(5): 775.

Thévenot F. Sintering of boron carbide-silicon carbide two-phase materials and their properties, J. Nucl. Mater., 1988, 152(2–3): 154.

Heian E.M., Khalsa S.K., Lee J.W., and Munir Z.A., Synthesis of dense, high-defect-concentration B4C through mechanical activation and field-assisted combustion, J. Am. Ceram. Soc., 2004, 87(5): 779.

Marianna K., Christoper S.M., and Andreas M., Effect of reaction on the tensile behavior of infiltrated boron carbide-aluminum composites, Mater. Sci. Eng. A, 2002, 337(1–2): 264.

Adrian G., Yehoshua Y., and Ayala G., B4C/metal boride composites derived from B4C/metal oxide mixtures, J. Eur. Ceram. Soc., 2007, 27(2–3): 695.

Shi L., Gu Y.L., Chen L.Y., Qian Y.T., Yang Z.H., and Ma J.H., A low temperature synthesis of crystalline B4C ultrafine powders, Solid State Commun., 2003, 128(1): 5.

Yamada S., Hirao K., Yamauchi Y., and Kanzaki S., Mechanical and electrical properties of B4C-CrB2 ceramics fabricated by liquid phase sintering, Ceram. Int., 2003, 29(3): 299.

Sigl L.S., and Kleebe H.J., Microcracking in B4C-TiB2 composites, J. Am. Ceram. Soc., 1995, 78(9): 2374.

Tuffé S., Dubois J., Fantozzi G., and Barbier G., Densification, microstructure and mechanical properties of TiB2-B4C based composites, Int. J. Refract. Met. Hard Mater., 1996, 14(5–6): 305.

Skorokhod V. Jr., Vlajic M.D., and Krstic V.D., Mechanical properties of pressureless sintered boron carbide containing TiB2 phase, J. Mater. Sci. Lett., 1996, 15(15): 1337.

Yamada S., Hirao K., Yamauchi Y., and Kanzaki S., Mechanical and electrical properties of B4C-CrB2 ceramics fabricated by liquid phase sintering, J. Eur. Ceram. Soc., 2003, 23(8): 1123.

Skorokhod V. and Krstic V.D., High strength-high toughness B4C-TiB2 composites, J. Mater. Sci. Lett., 2000, 19(3): 237.

Jung J. and Kang S., Advances in manufacturing boron carbide-aluminum composites, J. Am. Ceram. Soc., 2004, 87(1): 47.

Lee B.S., and Kang S., Low-temperature processing of B4C-Al composites via in filtration technique, Mater. Chem. Phys., 2001, 67(1–3): 249.

Srivatsan T.S., Guruprasad G., Black D., Radhakrishnan R., and Sudarshan T.S., Influence of TiB2 content on microstructure and hardness of TiB2-B4C composite, Powder Technol., 2005, 159(3): 161.

Bartolome J.F., Diaz M., Moya J.S. Influence of the metal particle size on the crack growth resistance in mullite-molybdenum composites. J. Am. Ceram. Soc., 2002, 85(11): 2778.

Cha S.I., Hon S.H., Ha G.H., and Kim B.K., Mechanical properties of WC-10Co cemented carbides sintered from nanocrystalline spray conversion processed powders, Int. J. Refract. Met. Hard Mater., 2001, 19(4–6): 397.

Dubey S., Srivatsan T.S., and Soboyejo W.O., Fatigue crack propagation and fracture characteristics of in-situ titanium-matrix composites, Int. J. Fatigue, 2000, 22(2): 161.

Yeomans J.A., Ductile particle ceramic matrix composites—Scientific curiosities or engineering materials, J. Eur. Ceram. Soc., 2008, 28(7): 1543.

Viala J.C., Bouix J., and Gonzalez G., Chemical reactivity of aluminum with boron carbide, J. Mater. Sci., 1997, 32(17): 4559.

Yamada S., Hirao K., Yamauchi Y., and Kanzaki S., High strength B4C-TiB2 composites fabricated by reaction hot-pressing, J. Eur. Ceram. Soc., 2003, 23(7): 1123.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lü, P., Yue, X., Ru, H. et al. Microstructure and mechanical properties of B4C-TiB2-Al composites fabricated by vacuum infiltration. Rare Metals 29, 92–97 (2010). https://doi.org/10.1007/s12598-010-0016-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-010-0016-4